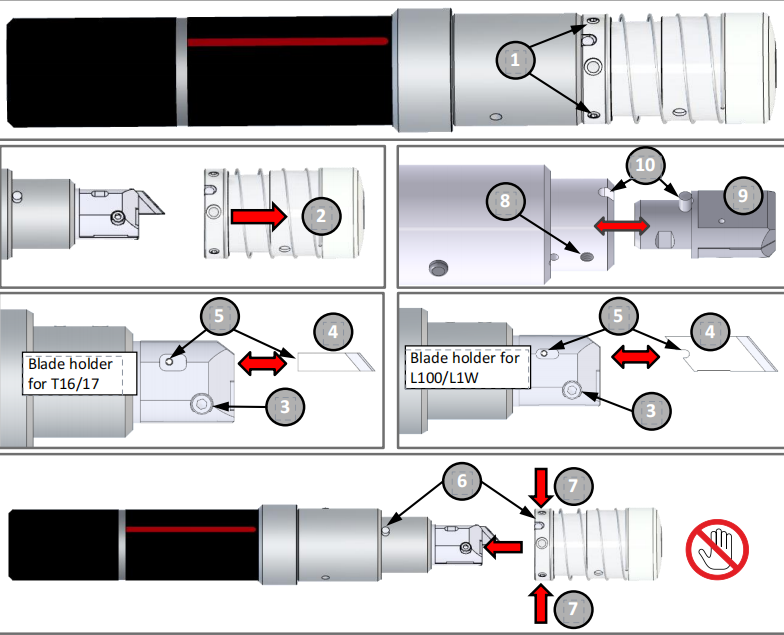

Note: Depending on the blades being used for the desired processes, the relative dedicated blade holder must be mounted (blade holder for L100 / L1W blades or blade holder for flat blades T16 / 17).

a)Loosen the locking set screws (1) and remove the movable blade guard (2) Figure 6-15.

Attention: If a blade holder equipped with a blade is already present on the tangential tool, first proceed with the disassembly of the latter in order to avoid possible accidental injuries (carry out point (e) and then resume the procedure from point b).

b)Loosen the set screw (8) and extract the blade holder (9).

c)Insert the desired blade holder with the reference pin (10) oriented as shown in the figure and make sure that it is entered up to the stop.

e) Loosen the blade cartridge screw (3) and remove the used blade (4) (if present).

f) insert a new blade (4) until the notch of blade reaches the pin (5), then tighten the screw (3).

g) Position the blade guard so that the reference pin matches its housing (6), then grab it from the sides (7) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

h) Tighten the locking set screws (1).

To replace a blade, carry out the procedure described above, skipping points b) c) d).

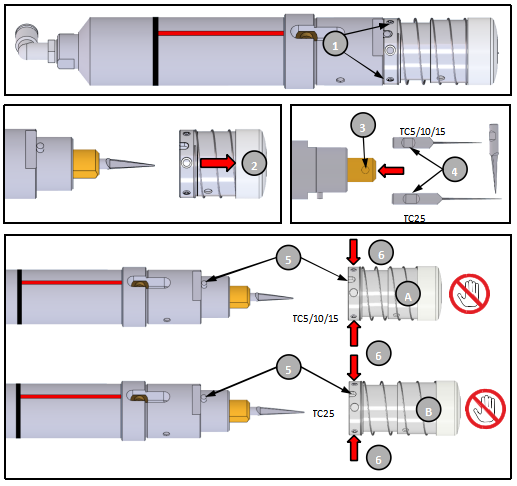

OSCILLATING CUTTING TOOL PREPERATION (OPTIONAL)

• Loosen the locking set screws (1) and remove the movable blade guard (2).

• Loosen the blade holder screw (3) and insert a new “TC” Type blade, paying attention that the blade notch (4) matches the locking screw and then push it inside until to the stop and tighten the screw (3).

• Position the blade guard (A) or (B), depending on whether we have chosen a TC5/10/15 or TC25 type, paying attention that the reference pin fits into its housing (5), then grab it from the sides (6) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

• Tighten the locking set screws (1)

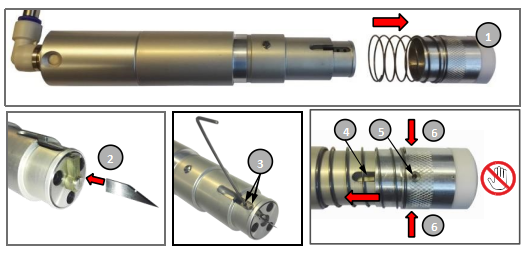

X TYPE OSCILLATING TOOL PREPARATION (OPTIONAL)

Remove the blade guard (1) by pulling it outwards.

• Insert a flat blade into its housing with the tip facing the center of the tool (2).

• Tighten the two blade locking set screws (3) with a 1.5mm Allen key

• Position the blade guard so that the reference pin (4) matches the sliding slot (5), then grab it from the sides (6) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

MultipurposeBlade. 50°AngleUniversal knife for materials such as paper,cardboard, thin plastic, soft PVC, Foam Board.

Multi-purpose Blade. 38 °Angle for a more precise cut on small radius. Universal knife for materials such as paper,cardboard,thin plastic.

Carbide multipurpose blade for a longer sharpening duration. 50 ° angle.Long lasting blade ideal forvery abrasive materials.(SeeL100)

Carbide multipurpose blade for a longer sharpeningduration and witha 38° angle for greater precision on cuts with a reduced radius. Long lasting blade ideal forvery abrasive materials. (See L100B)

Multipurpose T17 Blade, with a tighter angle for greater precision on cuts with a small radius. (25° Angle) Sole leather, cardboard, thin polyester. To make sharp edges.

T18 Heavy-Duty BladeVery rigid materials, sole leather, asbestos free, tang graphite, for thickness up to 5 mm.

T19 Blade –Soft RubbersSoft rubbers up to 12 mm thick.002733T21 Blade –Double Edge HD Blade

002720 TC 5mm

001899 TC 10mm Blade

001898 TC 15mm Blade

001897 TC 25mm Blade

Gasket material, solid cardboard, foam cardboard, foamboard with paper surface, foamed materials, soft foam panels, corrugated cardboard, packaging material, honeycomb cardboard.

PREV : Kimla Replacement Oscillating Knife Blades For Sale Shop NEXT : Summa Drag Vs. Tangential Knife Blades Technology For Vinyl Cutters