The Summa perforating tool for the F Series is used to make perforations in a very efficient and fast way. By using this tool, the perforated materials will be a lot easier to bend or fold. Then, the folds will have sharper 90° edges resulting in a nicer finish. This will save considerable time in the assembling of, for instance, cardboard or polypropylene boxes.

Strongest features

• Up to 25 times faster cutting of perforation lines (versus EOT tool)

• Alternative for creasing. Folding and bending lines into cardboard

• High-quality perforated cuts

• Several knives available

Ideal for cutting

• Solid cardboard

• Corrugated board

• Polypropylene film

Customer benefits

• Shorter cutting process

• Perforated lines will be easier to bend and process, saving labour and finishing costs

• Bending lines are more straight

Examples of the knives and their application

A. Perforating tool for cardboard, (example craft back 0,5 mm)Cardboard often used for small boxes Knife to use: 500-9891 (1.7x1.7mm D1.1mm) or 500-9890 (1x1mm D1.1mm) Application: Instead of creasing, the cardboard can be perforated, which will result in cuts that are much easier to bend. The perforation cut is done on the printed side. For

optimal results, the creasing and cutting are done at the rear side of the cardboard.

B. Perforating tool for cutting corrugated (example: E-flute 1,5 mm) Knife to use: 500-9892 (3x3mm D4mm) or 500-9893 (5x5mm D4mm)

Application: Also in this case the perforated material will be easier to bend as opposed to creasing. The best result is obtained when creasing is combined with perforated cuts.This way, the perforated cardboard bends perfectly 90°. For optimal results, creasing,perforating and cutting are done at the rear side of the cardboard.

C. Perforating tool for cutting Polypropylene (example: 0,8 mm PP) Used to produce small boxes, maps, etc.

Knife to use: 500-9891 (1.7x1.7mm D1.1mm) or 500-9890 (1x1mm D1.1mm)

Application: When processing perforated cuts in polypropylene sheets, it will be easier to bend the folding lines. The best result is obtained when the material surface is first slightly cut at the material surface with the kiss-cut tool. The usage of the perforation tool afterwards, will give it a nice finish. It is perfectly possible to bend 90° and maintain a clean folding line that can be folded durably several times.

Practical information Minimum system requirements GoProduce V2.3 Firmware Version 39 Recommended options An additional tangential module may be needed because the perforating tool will probably be used in combination with cutting and creasing tools. Tip: when using three tangential modules, make sure the left ADC is installed.

Perforating tool The tool standard included three perforation knives 500-9891 / 500-9892 / 500-9893

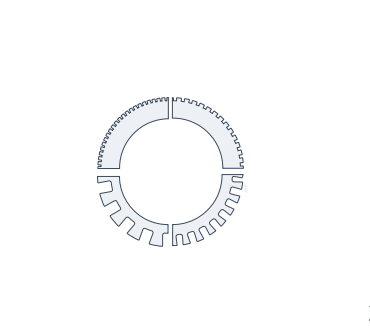

Perforation Knives:

500-9890 Perforation Knife 1 x1 mm D1.1 mm (12TPI)

500-9891 Perforation Knife 1.7 x1.7 mm D1.1mm (8TPI)

500-9892 Perforation Knife 3x3 mm D4 mm (4 TPI)

500-9893 Perforation Knife 5x5 mm D4 mm (3TPI)

PREV : Special carbide blades for Jwei vibrating knife cutting machine NEXT : Optional Supply Items / Standard Accessories