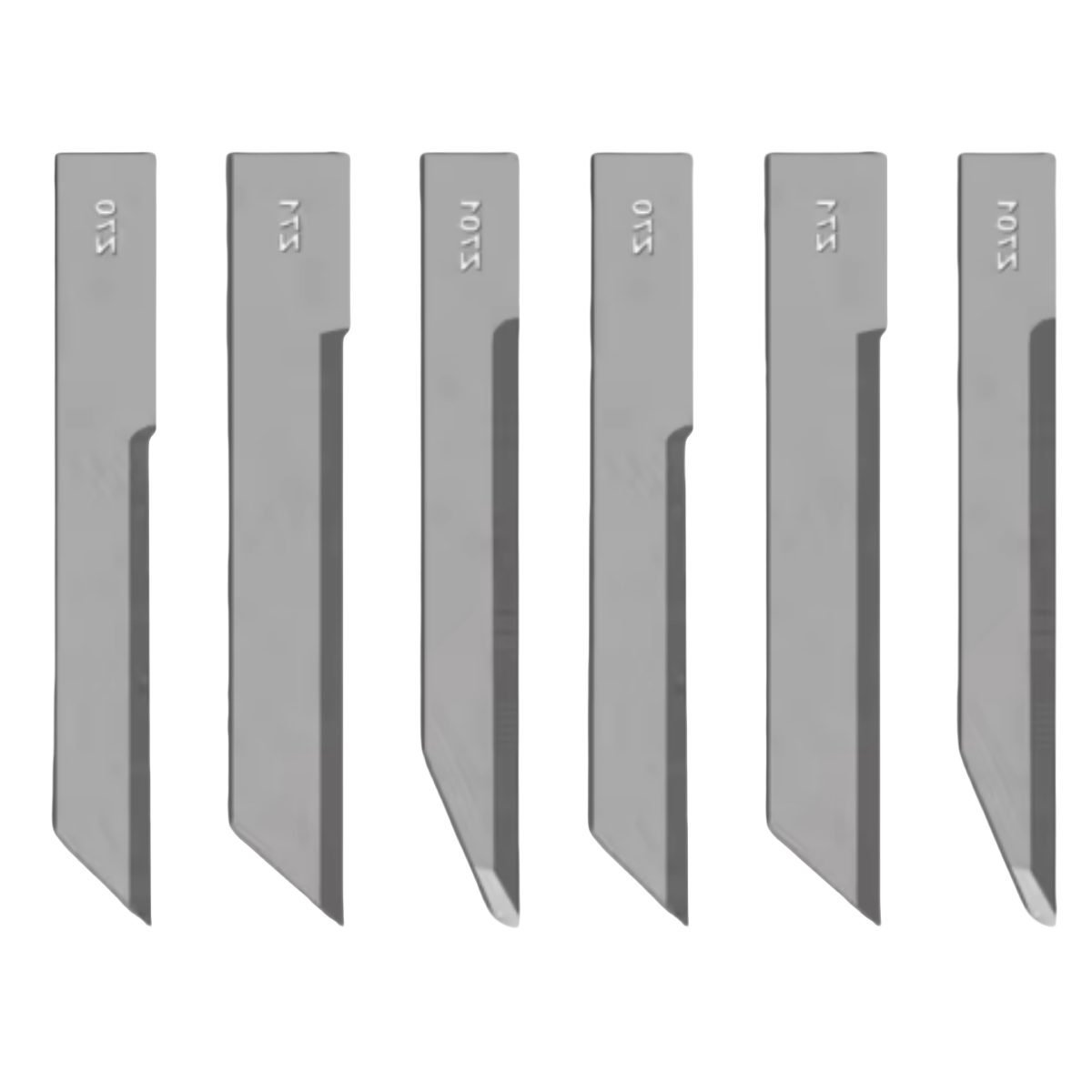

What Is The Difference Between The Zund Z70 Z71 Z701 Cutter Tungsten Carbide Blades?

The Zund Z70, Z71, and Z701 cutters are high-performance digital cutting machines commonly used in various industries like sign-making, packaging, and textile production. These cutters are known for their precision and versatility, and they use Tungsten Carbide blades for cutting a wide range of materials. However, the primary difference between the models lies in their capabilities, the types of materials they can handle, and the design of the blades.

Key Differences in Tungsten Carbide Blades:

Zund Z70 Blade:

Designed For: This model is typically used for lighter cutting tasks.

Blade Design: The Z70 uses tungsten carbide blades that are good for cutting paper, light card, and thin materials.

Cutting Speed & Precision: It offers good precision but is optimized for applications that don’t require extreme cutting force or high-throughput production.

Zund Z71 Blade:

Designed For: The Z71 is often used for more demanding cutting tasks.

Blade Design: It uses tungsten carbide blades that are designed to withstand tougher materials such as thicker foams, thicker card stocks, and textiles.

Cutting Speed & Precision: The Z71 offers more power and speed compared to the Z70 and provides improved precision for heavier cutting tasks. The blade is designed for greater durability and longevity.

Zund Z701 Blade:

Designed For: This is the most advanced and robust of the three.

Blade Design: The Z701 has tungsten carbide blades optimized for the most demanding tasks, such as cutting through industrial-grade materials like thicker plastics, composites, or dense boards. These blades are engineered to last longer, even when cutting tough, abrasive materials.

Cutting Speed & Precision: The Z701 offers the highest cutting speed and precision, along with greater flexibility for industrial-scale applications. It's designed to handle very high-volume production with greater reliability and strength.

Summary:

Z70: Suitable for lighter materials and lower-demand applications.

Z71: Better for thicker and more demanding materials with higher precision and durability.

Z701: Best for industrial-grade materials, offering the highest durability, cutting power, and precision for large-scale operations.

Each of these models' tungsten carbide blades is designed to offer a balance between precision and durability, with the Z701 offering the greatest strength and versatility, suitable for heavy-duty use. Zund

PREV : iEcho machine tool blades and Zund machine tool blades common parts NEXT : Esko Kongsberg Zund Coated DLC Tungsten Steel Blades Introduction