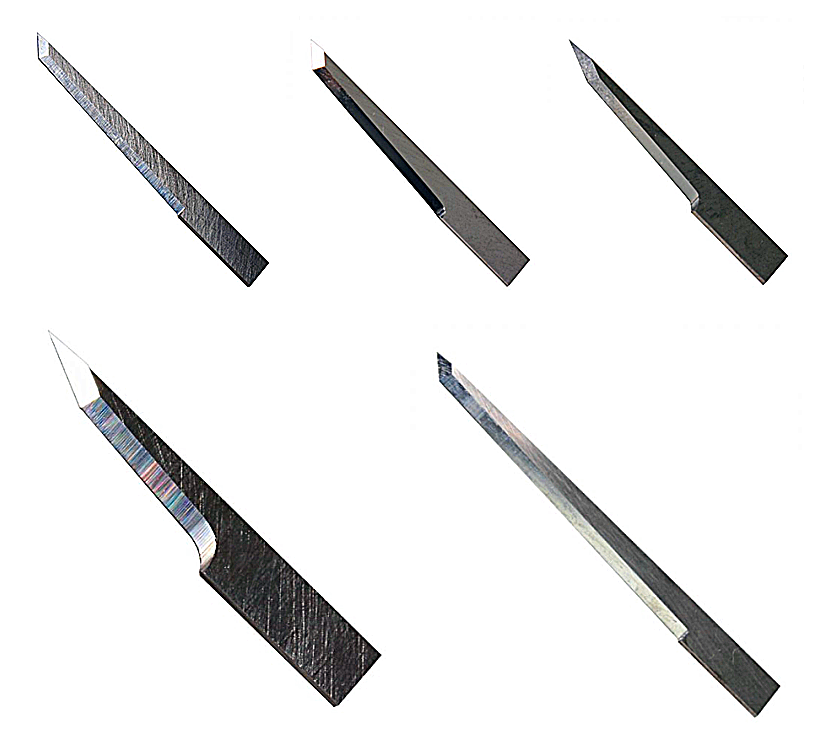

Choosing and using Colex oscillating knife blades, such as T00420, T00421, T00423, T00425, and T00428, involves understanding their specifications and applications. Here's a guide to help you select and utilize these blades effectively:

Understanding Colex Oscillating Blades

- T00420 (14mm, 9/16")**: Ideal for cutting corrugated stock, foam board, and Styrofoam up to 9/16". It provides clean edges and is suitable for materials requiring moderate thickness cutting.

- T00421 (18mm, 11/16"): Designed for thicker materials, including corrugated stock and foam boards up to 11/16". Offers greater stability and cutting power.

- T00423 (23mm, 7/8"): Suitable for honeycomb and Falcon boards, providing the strength needed for cuts up to 7/8".

- T00425 (25mm, 1"): Similar to T00423, it is designed for thicker materials like honeycomb and Falcon boards, handling cuts up to 1".

- T00428 (32mm, 1-1/4"): For the most demanding applications, this blade handles materials up to 1-1/4" thick.

Choosing the Right Blade

1. Material Thickness: Select a blade that matches the thickness of your material. For example, T00420 is suitable for materials up to 9/16" thick, while T00428 is for thicker materials up to 1-1/4".

2. Material Type: Different blades are optimized for specific materials. For instance, T00423 is ideal for honeycomb and Falcon boards.

3. Cutting Requirements: Consider whether you need clean edges, precision cuts, or the ability to handle complex shapes. Oscillating blades are versatile but may require adjustments for intricate cuts.

Using Colex Oscillating Blades

1. Installation: Ensure the blade is securely installed in the oscillating tool according to the manufacturer's instructions. Typically, this involves aligning the blade with the tool's holder and securing it with bolts or clips.

2. Adjustment: Adjust the blade's position and angle to optimize cutting performance. This may involve fine-tuning the blade's depth and alignment with the material.

3. Maintenance: Regularly inspect and clean the blade to maintain its cutting efficiency. Dull blades can lead to poor cuts and increased wear on the machine.

4. Safety Precautions: Always use protective gear when handling sharp blades, and ensure the cutting area is clear of debris to prevent accidents.

Understanding Colex Oscillating Blades

- T00420 (14mm, 9/16")**: Ideal for cutting corrugated stock, foam board, and Styrofoam up to 9/16". It provides clean edges and is suitable for materials requiring moderate thickness cutting.

- T00421 (18mm, 11/16"): Designed for thicker materials, including corrugated stock and foam boards up to 11/16". Offers greater stability and cutting power.

- T00423 (23mm, 7/8"): Suitable for honeycomb and Falcon boards, providing the strength needed for cuts up to 7/8".

- T00425 (25mm, 1"): Similar to T00423, it is designed for thicker materials like honeycomb and Falcon boards, handling cuts up to 1".

- T00428 (32mm, 1-1/4"): For the most demanding applications, this blade handles materials up to 1-1/4" thick.

Choosing the Right Blade

1. Material Thickness: Select a blade that matches the thickness of your material. For example, T00420 is suitable for materials up to 9/16" thick, while T00428 is for thicker materials up to 1-1/4".

2. Material Type: Different blades are optimized for specific materials. For instance, T00423 is ideal for honeycomb and Falcon boards.

3. Cutting Requirements: Consider whether you need clean edges, precision cuts, or the ability to handle complex shapes. Oscillating blades are versatile but may require adjustments for intricate cuts.

Using Colex Oscillating Blades

1. Installation: Ensure the blade is securely installed in the oscillating tool according to the manufacturer's instructions. Typically, this involves aligning the blade with the tool's holder and securing it with bolts or clips.

2. Adjustment: Adjust the blade's position and angle to optimize cutting performance. This may involve fine-tuning the blade's depth and alignment with the material.

3. Maintenance: Regularly inspect and clean the blade to maintain its cutting efficiency. Dull blades can lead to poor cuts and increased wear on the machine.

4. Safety Precautions: Always use protective gear when handling sharp blades, and ensure the cutting area is clear of debris to prevent accidents.

PREV : Duplo Pfi Blade B2+ And B3+ Digital Cutting Tables Blade Consumables List NEXT : JWei Milling & Router Bits J515 J516 J517 Difference Cutting Materials Application