How do the Esko Kongsberg Cutting Tables BLD-SR6223 compare to the BLD-SR6310 blades in terms of performance

The Esko Kongsberg BLD-SR6223 and BLD-SR6310 blades are both designed for use with Kongsberg cutting tables, but they differ in terms of performance, applications, and durability.

Comparison:

| Feature | BLD-SR6223 | BLD-SR6310 |

|---|---|---|

| Blade Type | Standard Drag Blade | Heavy-Duty Drag Blade |

| Material | Tungsten Carbide | Tungsten Carbide |

| Cutting Depth | Medium | Deeper cuts |

| Best For | Thin to medium materials | Thicker materials |

| Durability | Moderate | Higher durability |

| Applications | Vinyl, adhesive films, carton | Corrugated board, foam, and tougher materials |

Performance Differences:

-

The BLD-SR6223 is ideal for cutting lighter materials, providing precision in fine detail work.

-

The BLD-SR6310 is designed for heavier-duty applications, allowing for deeper cuts into thicker, denser materials.

-

The SR6310 blade generally lasts longer due to its stronger construction, making it more cost-effective for demanding jobs.

Which One to Choose?

-

If you frequently cut thin or delicate materials, the BLD-SR6223 is the better option.

-

If you're working with thicker, tougher materials, the BLD-SR6310 provides better longevity and cutting power.

Would you like recommendations based on a specific material or project?

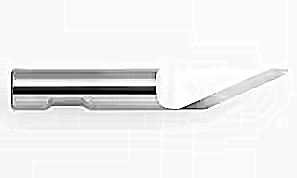

Esko Kongsberg Bld-Sr6310 Round Shank Knife Blade G42441626

Esko Kongsberg Bld-Sr6223 Round Shank Knife Blade G42437293

PREV : How do the Esko Kongsberg Cutting Tables BLD-SR6224 compare to the BLD-SR6223 blades NEXT : Esko Kongsberg System Bld-Sr6310 Bld-Sr6223 Bld-Sr6224 Single Edge Round Oscillating Blades