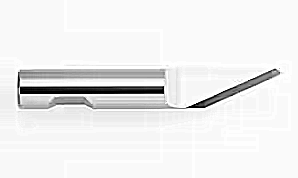

The BLD-SR6303 and BLD-SR6224 are both oscillating knife blades designed for use with Kongsberg cutting systems, each tailored for specific materials:

- BLD-SR6303: This blade features a 20mm cut length and is particularly well-suited for cutting materials such as foam, foam board, and corrugated plastic. Its design allows for efficient processing of these softer, thicker materials.

- BLD-SR6224: With a 12mm cut length and a 66-degree cutting angle, this blade is optimized for cutting corrugated board, especially those with high recycled content. Its sharp point and specific geometry make it effective for achieving clean cuts in such materials.

In summary, the BLD-SR6303 blade outperforms the BLD-SR6224 when cutting materials like foam, foam board, and corrugated plastic due to its longer cut length and design tailored for these substrates. Conversely, for corrugated boards, particularly those with high recycled content, the BLD-SR6224 is the more suitable choice.

Given these characteristics, the BLD-SR6303 blades might outperform the BLD-SR6224 blades in scenarios where:

1. Lighter Materials: They could be more effective for cutting lighter or less dense materials where precision and speed are more important than raw cutting power.

2. Specific Material Types: If there are specific types of materials that require a slightly different cutting edge or angle, the BLD-SR6303 might be more suitable.

However, without specific data or comparisons, these are general assumptions based on typical applications and characteristics of similar blades.

|

Esko Kongsberg Bld-Sr6224 Tungsten Carbide Round Shank Knife Blade G42438135 |

|

Esko Kongsberg Bld-Sr6303 Carbide Oscillation Knife Blade G42441642 |

PREV : JingWei JWei J202 Drag blade, round-stock Cutting material Application NEXT : What Are The Key Features Of The Esko Kongsberg Multi Purpose High-Frequency Knife Tool