Blackman & White offers a range of knife blades designed for different materials, primarily used in cutting applications for textiles, composites, foams, and other industrial materials. Below are the best-suited materials for various Blackman & White knife blades:

1. Straight Knife Blades

- Best for: Fabrics, Textiles, Vinyl, Soft Foams, Thin Plastics

- Usage:Ideal for clean and precise cutting of woven and non-woven materials.

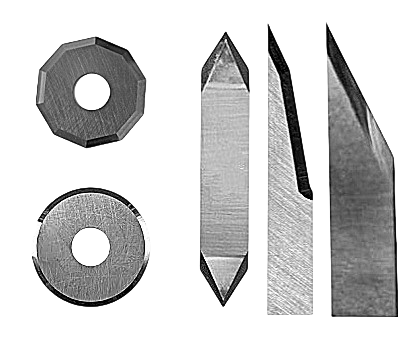

2. Rotary Knife Blades

- Best for:Leather, Carpet, Rubber, Technical Textiles

- Usage:Used for high-speed cutting of flexible materials while reducing drag.

3. Oscillating Knife Blades

- Best for: Foam, Cardboard, Corrugated Plastics, Gaskets

- Usage: Effective for materials that need precise cuts without fraying.

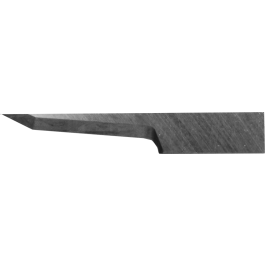

4. Drag Knife Blades

- Best for:Thin Plastics, Reflective Materials, Adhesive Vinyl, Paper

-Usage:Good for quick cuts with minimal wear, used in contour cutting applications.

5. Creasing Wheel Blades

- Best for: Cardboard, Packaging Materials, Corrugated Board

- Usage:Designed for scoring and creasing materials before folding.

6. Kiss Cut Blades

- Best for: Stickers, Decals, Laminated Films, Adhesive-Backed Materials

- Usage:Cuts the top layer without damaging the backing material.

If you're working with a specific material and need blade recommendations, I can help refine the best choice!

PREV : Cutworx LST 1319 & Max Series Digital Die Cutters Knife Blades Specifications and usage differences NEXT : JingWei JWei J202 Drag blade, round-stock Cutting material Application