The main differences between the BLD-SF186 and BLD-SF290 blades are primarily related to their design, application, and compatibility with specific materials and tools. Here's a comparison based on available information:

BLD-SF186 Blade

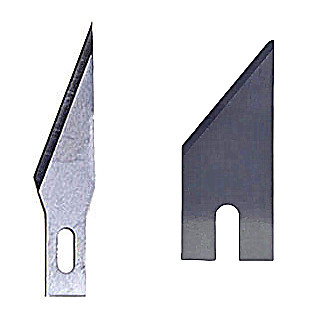

- Application: Typically used for cutting corrugated board and similar materials. It is part of the SFxxx series, which includes single-edge flat blades suitable for various applications, including corrugated board with high recycled content.

- Material Compatibility: Suitable for lighter materials like single and double-wall corrugated boards.

- Design and Features: Precision ground edge made of high-speed steel, which enhances durability and cutting efficiency.

BLD-SF290 Blade

- Application: Specifically designed for high-speed straight cutting in rigid boards such as fluted core board, honeycomb board, and triple wall corrugated.

- Material Compatibility: Ideal for denser materials like fluted core board and honeycomb board.

- Design and Features: Part of the RBI90-16 tool setup, which is optimized for high-speed cutting of straight lines in rigid materials.

Key Differences

- Material Compatibility: BLD-SF186 is better suited for lighter materials like corrugated boards, while BLD-SF290 is designed for denser, rigid materials.

- Application: BLD-SF186 is versatile for general cutting tasks, whereas BLD-SF290 is specialized for high-speed cutting in rigid boards.

- Design and Purpose: The BLD-SF290 is part of a specific tool setup (RBI90-16) designed for high-speed straight cutting, whereas BLD-SF186 is more commonly used across various applications.

In summary, the BLD-SF290 is optimized for high-speed cutting in rigid materials, while the BLD-SF186 is more versatile and suitable for lighter materials like corrugated boards.

|

Feature |

||

|

Edge Angle |

21° |

45° |

|

Material Thickness |

Cuts materials up to about 16mm |

Cuts materials up to 16mm |

|

Material Type |

Suitable for fluted core boards and triple wall corrugated |

Suitable for cardboard, corrugated cardboard, folding carton, and paper |

|

Knife Type |

Not specified as V-cut |

Flat, V-cut |

|

Application |

General cutting of various materials |

Specifically designed for the RB90-16 insert tool |

Both blades are designed for cutting various materials but differ in edge angle and specific application. The BLD-SF290 is specifically made for the RB90-16 tool and has a V-cut design, which may offer better performance in certain materials like cardboard and corrugated cardboard.

PREV : What Are The Main Differences Between The Esko Kongsberg Bld-Sf290 And Bld-Df570 Knife Blade NEXT : How To Choose And Use Esko Kongsberg Bld-Sf290 Flat,Pulling And Oscillating Knife Blades