1. Regular Cleaning

- Method: Use a soft brush or cloth to remove any debris or residue from the blade. This is crucial for maintaining cutting efficiency and preventing damage.

- Frequency: Clean the blade regularly, especially after each use to prevent buildup.

2. Inspection and Replacement

- Check for Wear: Regularly inspect the blade for signs of wear or damage. If the blade is dull or damaged, it should be replaced.

- Replacement: Use high-quality replacement blades that are compatible with your Eastman drag knife setup.

3.Adjusting Cutting Depth

- mportance: Properly adjust the cutting depth to avoid excessive wear on the blade. Start with a shallow depth and increase as needed.

-Testing: Always test the cutting depth on a scrap piece of material before starting your actual project.

4. Material Preparation

- ecuring Material: Ensure that the material is properly secured with clamps or adhesive tape to prevent movement during cutting. This helps maintain blade integrity and ensures precise cuts.

5.Sharpening

- While drag knives are typically not sharpened like traditional knives, maintaining sharpness is crucial. If your setup allows for sharpening, follow the manufacturer's guidelines for sharpening procedures.

6. Storage

- Dry Environment: Store the blade in a dry environment to prevent rust or corrosion.

-Protective Coating: Consider applying a thin layer of oil or rust inhibitor if you live in a humid area to protect the blade from corrosion.

By following these maintenance tips, you can extend the life of your Eastman drag knife blade and ensure it continues to perform optimally.

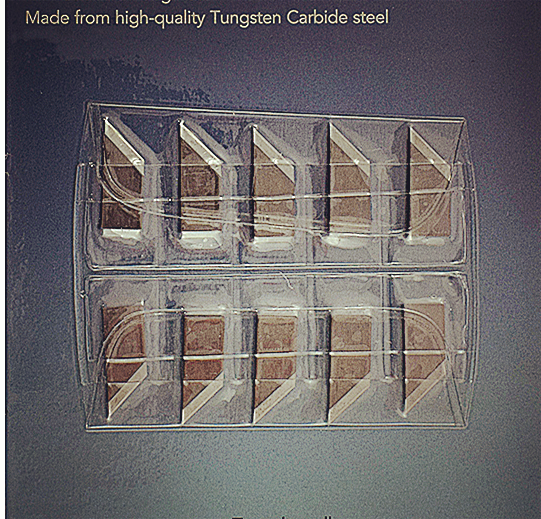

PREV : How To Choose The Filiz Rotation Knife Blade And Usage Tips NEXT : Eastman 54-26011-1-2-3-4-5 Tungsten Carbide Steel Drag Knife Blade