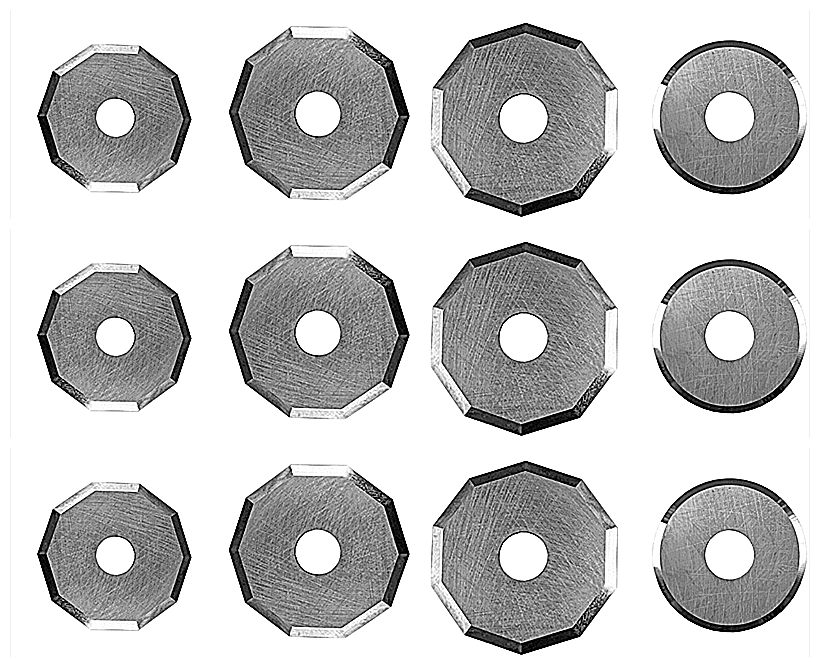

1.Filiz F50 Rotation Knife Blade: This blade has a 36° angle, 0.60 mm thickness, and a maximum cutting depth of 5.00 mm. It's suitable for materials like aramid fibers, carbon fibers, felt, glass fibers, non-woven fabric, nylon fabric, polyester fabric, and textiles.

2. Filiz F50 DLC Coated Rotation Knife Blade:

- Description: This blade is designed for cutting a variety of materials such as aramid fibers, carbon fibers, felt, glass fibers, and more. It features a DLC coating for extended durability.

- Features: The blade has a thickness of 0.60 mm, a cutting angle of 36°, and a maximum cutting depth of 5.00 mm. It is suitable for rotary cutting applications.

- Advantages: The DLC coating enhances the blade's lifespan, making it a good choice for heavy-duty use.

-Drawbacks: It might be more expensive than non-coated options.

3. Filiz F51 Rotation Knife Blade:

- Description: Similar to the F50, the F51 is also a rotary blade designed for cutting various materials. It has a knife height of 28.00 mm and the same thickness and cutting angle as the F50.

- Features: It offers versatility in cutting different fabrics and materials.

- Advantages: It provides consistent performance and is suitable for a range of applications.

- Drawbacks: It lacks the DLC coating, which might reduce its lifespan compared to the F50.

4. Filiz F52 Rotation Knife Blade:

- Description: This blade has a slightly taller knife height of 32.00 mm compared to the F51. It is also designed for rotary cutting applications.

- Features: It offers similar versatility in material cutting.

- Advantages: The taller height might be beneficial for thicker materials.

- Drawbacks: It might not be as suitable for applications requiring a lower profile.

When choosing a Filiz Rotation Knife Blade replacement, consider the specific materials you need to cut and the desired blade height and durability. The DLC coating on the F50 model offers enhanced longevity, while the F51 and F52 models provide versatility in different cutting tasks.

Using a Filiz rotation knife blade (commonly used in textile, leather, or industrial fabric cutting machines) requires strict safety precautions. These blades are extremely sharp and rotate at high speeds, so proper handling is crucial. Here's a list of use precautions to follow:

Before Use

1. Read the manual – Always consult the manufacturer's safety and operation guide.

2. Wear protective gear – Use cut-resistant gloves, safety glasses, and non-slip footwear.

3. Inspect the blade – Check for cracks, dullness, or damage. Never use a damaged blade.

4. Secure the work area – Ensure a clean, stable surface with no distractions or loose items nearby.

During Use

1. Never touch the blade while it’s rotating – Keep hands and tools away.

2. Use with a guide or fixture – Avoid freehand cutting unless the equipment is specifically designed for it.

3. Watch the power cord – Keep it away from the blade to prevent accidental cuts or shorts.

4. Keep focus – Stay alert and avoid multitasking or distractions.

5. Use proper pressure – Don’t force the material; let the blade do the cutting.

After Use

1.Turn off the machine– Wait for the blade to come to a full stop before handling or cleaning.

2. Clean carefully– Wipe down the blade without direct hand contact; use tools or thick cloth.

3. Store safely– Keep blades in protective covers or designated holders.

4. Regular maintenance – Sharpen or replace blades as needed and check alignment.

PREV : How To Choose Summa T Series 390-534 390-550 390-551 390-560 Carbide Tangential Blade And Usage Tips NEXT : What Is The Best Way To Maintain An Eastman Drag Knife Blade