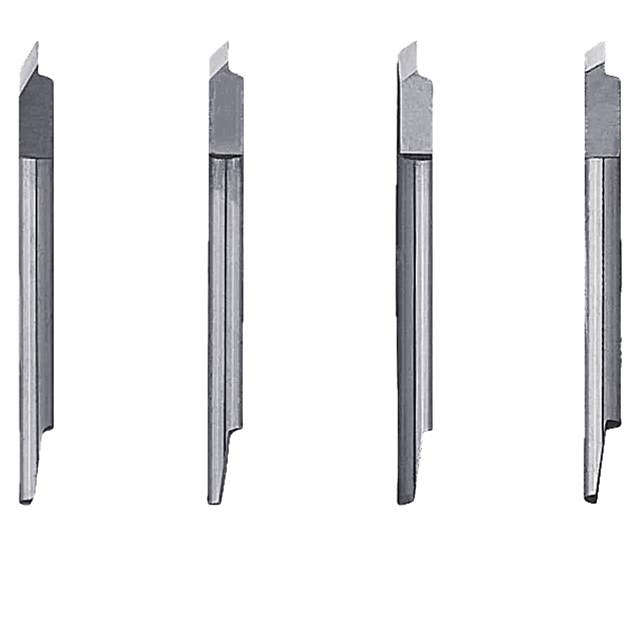

Overview of Each Blade

| Blade Model | Angle | Ideal For | Key Features |

|------------|--------|-----------------------------------------------|-------------------------------------------------------------|

| 390-534 | 36° | Standard vinyl, thin films | General-purpose blade for common cutting tasks |

| 390-550 | 45° | Thicker vinyl, reflective materials | Steeper angle for tougher materials |

| 390-551 | 60° | Sandblast stencil, thick media | Very steep angle for hard/thick materials |

| 390-560 | 36° | Textiles, window tint | Specialized for softer or delicate materials |

How to Choose the Right Blade

1. Material Type:

-Standard Vinyl, Fluorescents → Use 390-534 (36°)

-Reflective or Metallic Film → Use 390-550(45°)

-Sandblast Stencil, Cardboard, Rubber → Use 390-551 (60°)

-Textiles, Tint Film, Delicate Media → Use 390-560 (36° but optimized for soft)

2. Material Thickness:

- < 0.25 mm (0.01") → 36° blade

- 0.25 mm – 0.5 mm (0.01–0.02") → 45° blade

- > 0.5 mm (0.02")** or rigid → 60° blade

3. Cutting Detail Required:

- More intricate cuts = shallower angle (36°)

- Stronger cuts (less detail) = steeper angle (45° or 60°)

Usage Tips

- Blade Depth: Set the blade so it just barely scores the backing paper. Too deep = fast wear & poor cuts.

- Cutting Strip: Keep it clean and undamaged—this affects cut quality!

- Blade Holder Maintenance: Clean regularly and ensure bearings move smoothly.

- Speed & Force Settings:

- Start with manufacturer’s recommended settings.

- Do a test cut first.

- Adjust force if corners lift or lines aren’t clean.

Maintenance Tips

- Clean the blade tip regularly (especially after cutting adhesives).

- Rotate or replace the cutting strip if you notice inconsistent cut depths.

- Store unused blades in a dry, dust-free place to avoid corrosion.

Would you like a quick cheat sheet for material/blade matching or help choosing based on a specific project you're working on?

PREV : What are the main differences between Summa T series 390-534, 390-550, 390-551, and 390-560 blade NEXT : How To Choose The Filiz Rotation Knife Blade And Usage Tips