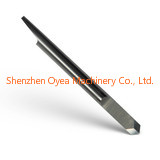

Blade Comparison

1.390-534 Blade:

- Angle: Typically a 36° blade.

- Material Compatibility: Suitable for cutting soft materials like standard vinyl, thin foils, and polyester fabric.

- Cutting Depth: Up to 0.25 mm (10 mil).

- Use Case: Ideal for precise cuts in soft materials.

2. 390-550 Blade:

- Angle: Typically a 60° blade.

- Material Compatibility: Designed for cutting thicker or tougher materials such as sandblast, rhinestone, reflective vinyl film, and cardboard.

- Cutting Depth: Up to 1.2 mm.

- Use Case: Best for materials requiring deeper cuts and precision in thicker or tougher materials.

3. 390-551 and 390-560 Blades:

- Specific details are not provided, but they likely cater to specific material types or thicknesses similar to the 390-534 and 390-550 blades.

Key Differences

- Angle and Material Compatibility: The angle of the blade affects its ability to cut through different materials. A higher angle (like 60°) is better for thicker materials, while a lower angle (like 36°) is more suitable for softer materials.

- Cutting Depth: The 390-550 blade can cut significantly deeper than the 390-534 blade, making it more versatile for thicker materials.

- Precision and Use Cases: Both blades are designed for precision cutting, but the choice depends on the specific material and project requirements.

For precise information about the 390-551 and 390-560 blades, it is recommended to consult Summa's official documentation or contact their customer support.

Additional Tips for Choosing the Right Blade

- Material Thickness: Ensure the blade can handle the thickness of your material.

- Cutting Speed and Pressure: Adjust these settings based on the material type for optimal results.

- Blade Maintenance: Regularly inspect and clean the blade to maintain performance.

PREV : What materials are suitable for Summa T series blades? NEXT : How To Choose Summa T Series 390-534 390-550 390-551 390-560 Carbide Tangential Blade And Usage Tips