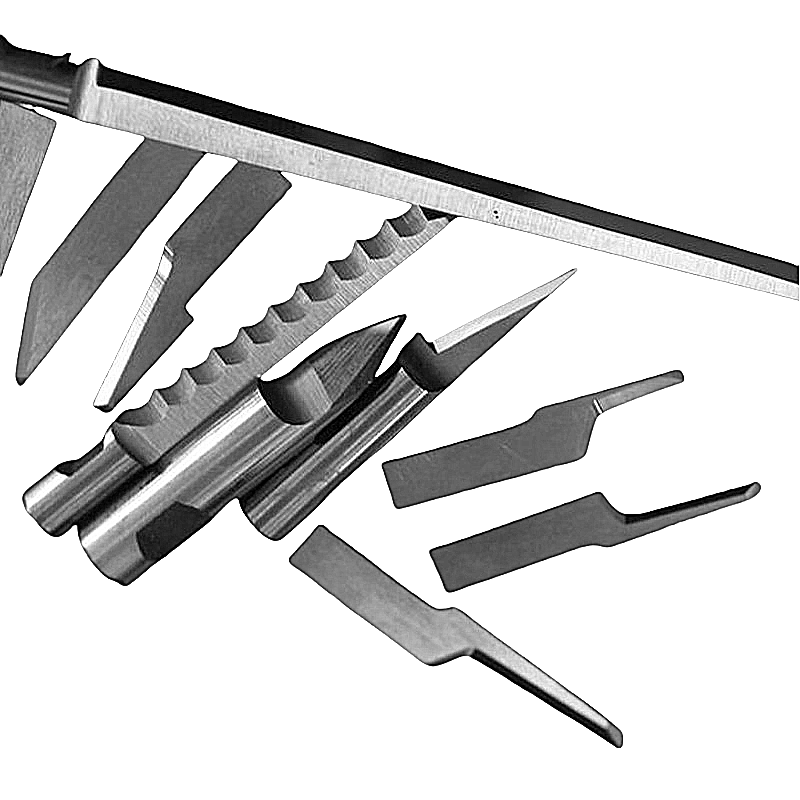

Solid carbide knife blades are cutting tools made entirely from tungsten carbide, a composite material composed primarily of tungsten and carbon atoms, often bound with a small amount of cobalt. These blades are known for their exceptional hardness, durability, and wear resistance, making them ideal for demanding industrial cutting applications.

Properties of Solid Carbide Knife Blades:

-

Extreme Hardness

-

One of the hardest materials used in cutting tools, second only to diamond.

-

Maintains sharpness longer than steel blades.

-

-

High Wear Resistance

-

Excellent resistance to abrasion and deformation.

-

Ideal for cutting tough materials like composites, rubber, paper, plastic, metal foils, and laminates.

-

-

High Heat Resistance

-

Withstands high temperatures without losing its hardness.

-

Suitable for high-speed cutting operations.

-

-

Brittleness

-

Despite being hard, carbide is more brittle than steel.

-

Can chip or break under excessive impact or if used improperly.

-

-

Corrosion Resistance

-

Better resistance to corrosion than high-speed steel (HSS), especially when bonded with cobalt.

-

-

Precision and Stability

-

Allows for precision cutting with minimal blade deflection.

-

Maintains edge geometry over long production runs.

-

Advantages:

-

Long tool life = less frequent blade changes

-

High cutting quality and consistency

-

Reduced downtime and maintenance

Considerations:

-

Higher upfront cost than steel blades

-

Requires careful handling to avoid chipping

-

Needs specialized equipment for sharpening or replacement

Solid carbide knife blades are versatile and are used across various industries for cutting different materials:

- Paper and Pulp: Ideal for cutting paper and cardboard due to their precision and durability.

- extiles: Suitable for cutting fabrics and other textile materials.

- Food Processing: Used in applications where cleanliness and precision are essential.

- Plastics and Films: Excellent for cutting high-density plastic films, multilayer films, and laminated films.

- Metalworking: Used in slitting and shearing tools for metal processing.

- Fiber Materials: Carbide blades are effective in cutting chemical fibers due to their chemical inertness and precision cutting capabilities.

Overall, solid carbide knife blades are preferred in applications requiring high durability, precision, and resistance to wear and corrosion.

OYEA: Offers a wide range of solid tungsten carbide knives specifically designed for Zund, Summa, iEcho, ESKO, Roland, Atom, Aristo, Jwei, and Gerber machines. They also offer custom blade design.

Supplies tungsten carbide oscillating knives and other types of blades compatible with various CNC cutting machines, including iEcho, Jwei, Atom, and Elitron.

PREV : Multicam K28 K32 K34 K36 Solid Carbide Round Shank Kiss Cut Blade Specifications And Usage Options NEXT : Zund Z201 Z202 Z203 Oscillating Knife Blades Specifications And Dimensions Use