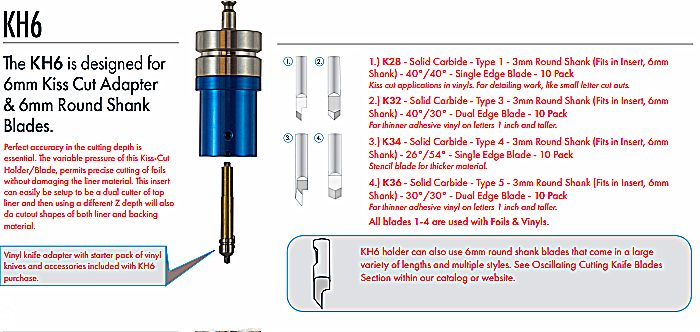

Kiss cut applications in vinyls. For detailing work, like small letter cut outs.

2.) K32 - Solid Carbide - Type 3 - 3mm Round Shank (Fits in Insert, 6mm

Shank) - 40°/30° - Dual Edge Blade

For thinner adhesive vinyl on letters 1 inch and taller.

3.) K34 - Solid Carbide - Type 4 - 3mm Round Shank (Fits in Insert, 6mm

Shank) - 26°/54° - Single Edge Blade

Stencil blade for thicker material.

4.) K36 - Solid Carbide - Type 5 - 3mm Round Shank (Fits in Insert, 6mm

Shank) - 30°/30° - Dual Edge Blade

The MultiCam K28, K32, K34, and K36 are solid carbide kiss-cut blades designed for precision cutting applications. Each blade features a round shank and is tailored for specific materials and cutting requirements. Below are the specifications and differences among these blades:

K28 Kiss Cut Blade:

Shank Diameter: 3mm round shank

Cutting Angle: 40°/40° single edge

Applications: Ideal for detailed work in vinyl materials, such as small letter cutouts

Additional Info: Suitable for applications requiring precision in intricate designs

K32 Kiss Cut Blade:

Shank Diameter: 6mm round shank

Applications: Typically used for cutting thin materials like vinyl, where precise depth control is essential

multicamtooling.com

Additional Info: Designed for kiss-cutting applications requiring a larger shank for stability

K34 Kiss Cut Blade:

Shank Diameter: 6mm round shank

Applications: Suited for materials such as thin films and adhesive-backed substrates

Additional Info: Offers enhanced control for detailed kiss-cutting tasks

K36 Kiss Cut Blade:

Shank Diameter: 6mm round shank

Applications: Designed for cutting slightly thicker materials while maintaining precision

Additional Info: Provides versatility for a range of kiss-cutting applications

Key Differences:

Shank Diameter: K28 features a 3mm shank, while K32, K34, and K36 have 6mm shanks, affecting compatibility with different tool holders and stability during cutting.

Cutting Angle: The K28 has a specified 40°/40° single edge, whereas the exact cutting angles for K32, K34, and K36 are not specified.

Applications: Each blade is optimized for specific materials and cutting tasks, with the K28 focusing on intricate vinyl work and the others accommodating a range of materials with varying thicknesses.

When selecting a blade, consider the material type, thickness, and the precision required for your specific application to ensure optimal performance.

PREV : Multicam 003612-MC50 003612-MC51 003612-MC52 ROTARY Decagonal (10-Sided) Rotation Knife Blade NEXT : What Is Solid Carbide Knife Blades And What Are Its Properties?Application Range