Tungsten Carbide Cutting Knife Blades(TC Knife Blade) - China Manufacturers, Suppliers, Factory

Tungsten Carbide Blades Manufacturing Overview

If you're interested in the production process, here's a simplified outline:

-

Raw Materials Preparation

-

Tungsten powder (W) is mixed with carbon black to form tungsten carbide (WC).

-

A binder metal, typically cobalt (Co), is added to hold the carbide grains together.

-

-

Mixing and Milling

-

Powders are ball-milled with a binding agent and drying additives.

-

This forms a homogenous powder mixture.

-

-

Pressing/Forming

-

The powder is compacted into a “green compact” using cold pressing (or extrusion for some shapes).

-

Isostatic pressing may also be used for uniform density.

-

-

Pre-Sintering

-

Light heating removes binders and increases strength without full densification.

-

-

Sintering

-

The compact is sintered at 1,400–1,600°C in a vacuum or controlled atmosphere.

-

This creates a dense, hard carbide structure.

-

-

Finishing

-

Grinding, EDM (electrical discharge machining), and sometimes coating (e.g., TiN, TiAlN) for sharper, wear-resistant edges.

-

By Application:

Industrial Cutting Blades,Used in converting, packaging, printing, and textile industries.,Woodworking Blades,Circular saws, router bits, planer knives,Metal Cutting Blades

For steel, aluminum, and other metals,Plastic & Rubber Cutting Blades,Granulator and shredder blades,Food Processing Blades,Clean, sanitary cuts in frozen or fresh products,Paper & Pulp Blades,Slitter and guillotine blades.

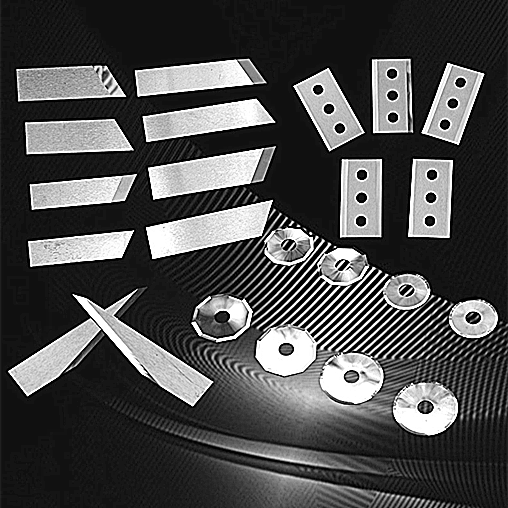

By Blade Type:Circular Blades,Straight Blades,Toothed Blades,Serrated Blades,Rotary Blades,Knives & Inserts

By Coating or Treatment:Uncoated Tungsten Carbide,Titanium Coated,Ceramic Coated,Diamond Coated (PCD Tips)

By Industry;Automotive,Aerospace,Packaging,Textiles,Medical,Construction

Key Features

Extreme Hardness: Second only to diamond.

Long Service Life: Retains edge sharpness longer than steel.

Heat Resistance: Ideal for high-speed cutting.

Precision Cutting: Clean, consistent cuts with minimal burring.

Corrosion Resistance: Withstands exposure to moisture and chemicals.

Customization Options:Blade diameter, thickness, and bore,Edge geometry (flat, beveled, serrated),Surface coatings for extended performance,OEM/ODM manufacturing support

Specialized in manufacturing the following blades:

Zund / Wild

Esko / Kongsberg

Martor

Aristo

Axyz

Bullmer

Summa

EcoCam

iEcho

Atom

Elcede

Sinajet

Stepcraft

Elitron

Comelz

MultiCam

JWEI

Colex

etc.

PREV : MultiCam 84-00193-BT-562090 AXYZ B2031L-90 double- edged Round Shank Knife Blade NEXT : JWEI J371 J373 J374 J374-B J375 J376 J377 J378 Tungsten Steel Round Knife Blade Specifications Size